Elb-Schliff and aba Grinding Technologies are both members of AUTANIA AG, a group of machine tool manufacturers with technology oriented solutions for complete multifunctional processing of complex components, surface and profile grinding and metal forming technologies.

Elb-Schliff and aba Grinding Technologies are both members of AUTANIA AG, a group of machine tool manufacturers with technology oriented solutions for complete multifunctional processing of complex components, surface and profile grinding and metal forming technologies.

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 60 years in Babenhausen (Hessen), Germany.

Today’s product line includes surface, profile and creep-feed grinding machines as well as a wide range of highly efficient production systems. Based on the decades of ELB-Schliff’s experience, there is hardly a grinding problem which has not already been solved.

BG: Traveling table / column machine for broaches

Benefit Overview

Benefit Overview

- High-precision profile machine for tool and mold industry

- Good cost-performance ratio

- Flexible process guidance

- Robust design

- Easy to program

BGS: Broach Sharpening

Benefit Overview

Benefit Overview

- Efficient and economic sharpening of broaching tools

- Quick setup times when switching between circular and flat broaches

- Easy to program through parameter input

- Measuring probes to collect raw parts

- Measuring probes to quickly and easily gather the tools geometry for resharpening

ecoLine: Speed grinding with linear drive technology

Benefit Overview

Benefit Overview

- Wear resistant and quiet linear drive

- Table velocity up to 60 m/min

- High acceleration and deceleration of main axis

- Large grinding width

- Large variety of available options

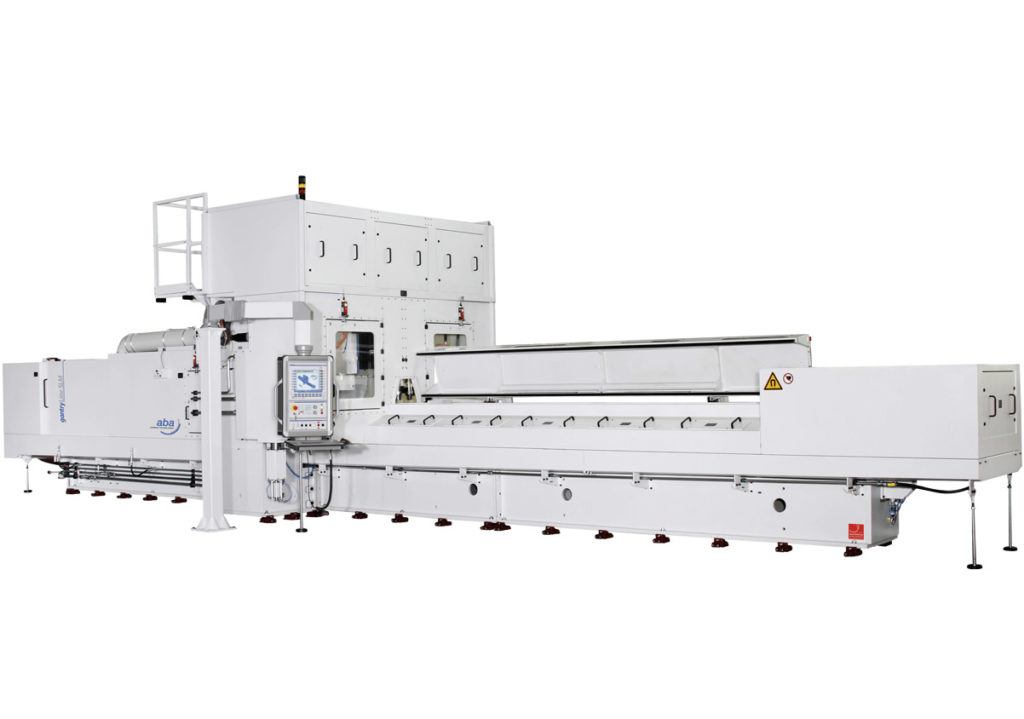

gantryLine: Precise and flexible processing of large work pieces

Benefit Overview

Benefit Overview

- Highest precision through gantry design

- High thermal stability

- Modular design

- Modern table drive system

- Multi-axes operation

gantryLine SLM: High-precision grinding of long work pieces

Benefit Overview

Benefit Overview

- X-axis with linear motor (60 m/min, no wear, quiet)

- High acceleration and deceleration of main axes

- High spindle power

- Various roll dressing units possible

- Flexible process guidance

microCut: Compact solution for creep-feed grinding

Benefit Overview

Benefit Overview

- Compact machine design

- High rate of material removal

- High long-term precision

- Ideal for cell layout

- Optional index table for loading/ unloading during grinding

- Automatic tool changer

millGrind: Multiple Technology Solution in one Set-Up

Benefit Overview

Benefit Overview

- Multiple Technology Solution in one Set-Up

- Automatic Tool and Diamond Roll

- Quick Change Over Time < 8 Sec.

- High Stock Removal Rate due to Continuous Dressing Capability

- Good Cost-Performance Ratio

- 2- or 3-Axes Rotary Tilt Tables as Option

- Automatic Workpiece Changing as Option

multiLine: Robust and economical

Benefit Overview

Benefit Overview

- Large cross reach

- Grinding spindle with pre-loaded precision bearings

- Very high table load capacity

- Large variety of options available

- Automatic tool changer

powerLine: Robust and economical

Benefit Overview

Benefit Overview

- Spindle power up to 105 kW

- Grinding spindle with pre-loaded precision bearings

- Capable to handle very high table loads

- Large variety of options available

rotary: Economical grinding of small work pieces

Benefit Overview

Benefit Overview

- Compact and robust machine design

- High productivity through continuous contact between wheel and work piece

- High long-term precision

- Precision rotary table

- Easy to operate

smartLine Kombi: The new standard in precision grinding

Benefit Overview

Benefit Overview

- Good cost-performance ratio

- High-powered spindle

- Roll dressing unit on spindle head

- Flexible process guidance

- Multi-axes machining

- Automatic tool changer